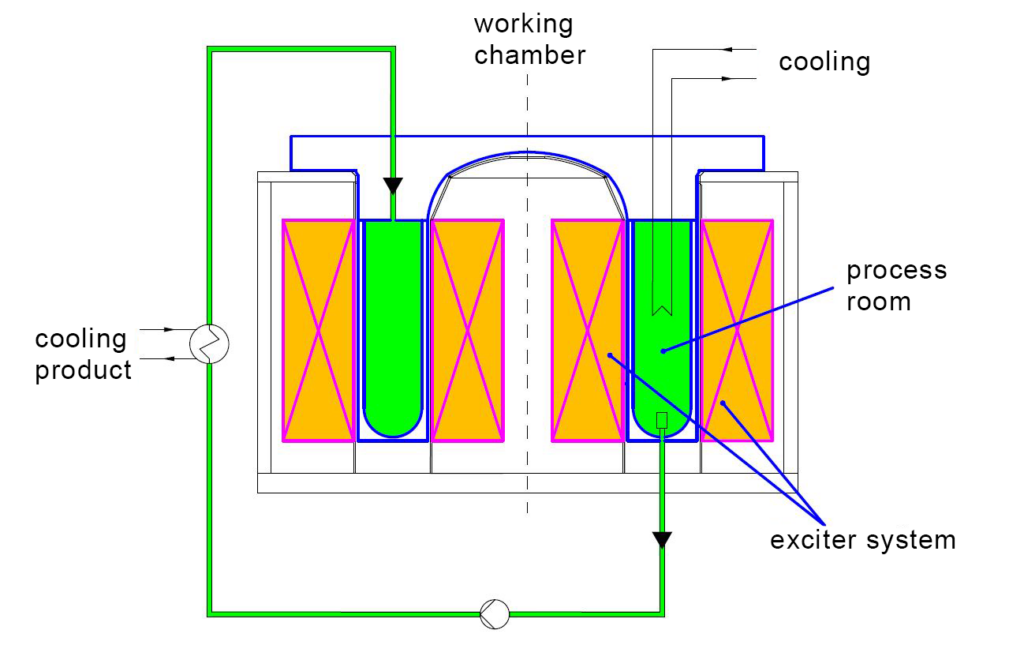

System

MAGNETIC FIELD MILL (MFM)

In magnetic field mills, the particles of the educt are mechanically

processed (e.g. milled, deagglomerated and/or dispersed) in a

closed working chamber by grinding media driven directly by the

magnetic field. For this purpose, a working chamber filled with

grinding media and educt is inserted into the drive from above.

By changing the strength and frequency of the magnetic field, the

grinding intensity can be precisely controlled over a wide range.

The grinding media drive can be used for dry and wet processing

tasks as well as for very small and large product quantities.

Depending on the design of the working chamber, the MFM can

be used in both batch filling and circulation mode.

The educt can be cooled directly in the working chamber.

The working chamber and grinding media can be designed to be

compatible with the product. Cleaning/ sterilization of the

working chamber is possible in the grinding media drive (CIP or

SIP).

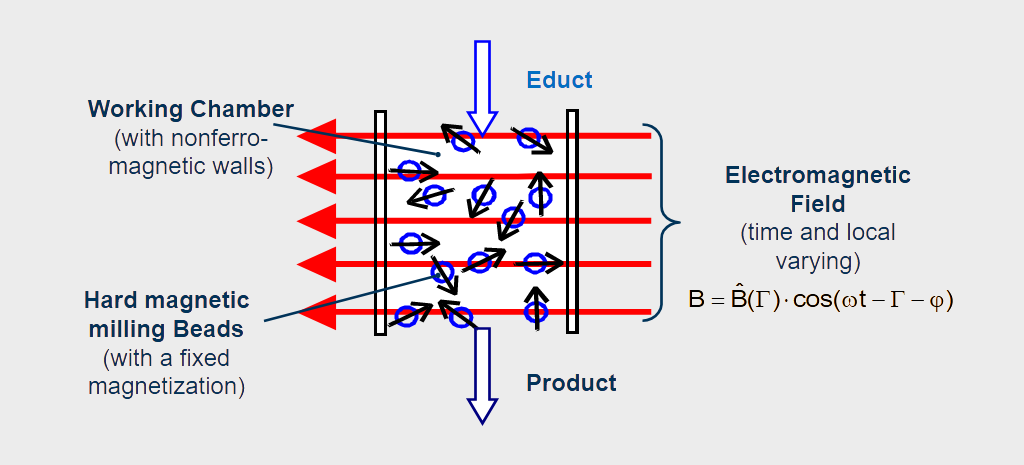

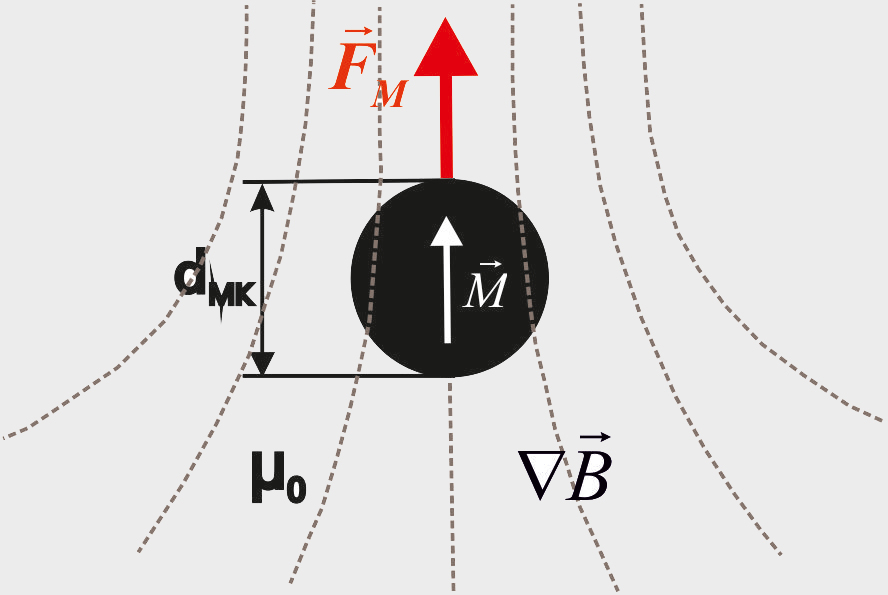

BASICS

to the electromechanical milling principle (EMZ)

the time and local varying electromagnetic field

on a milling bead with the magnetization M

UNIQUE SELLING POINTS

Thanks to the electromechanical milling principle, the innovative magnetic field mills are particularly impressive due to the

following unique selling points, such as:

- the simple mechanical design,

- ower energy consumption,

- low maintenance and cleaning costs,

- the processing in closed systems.